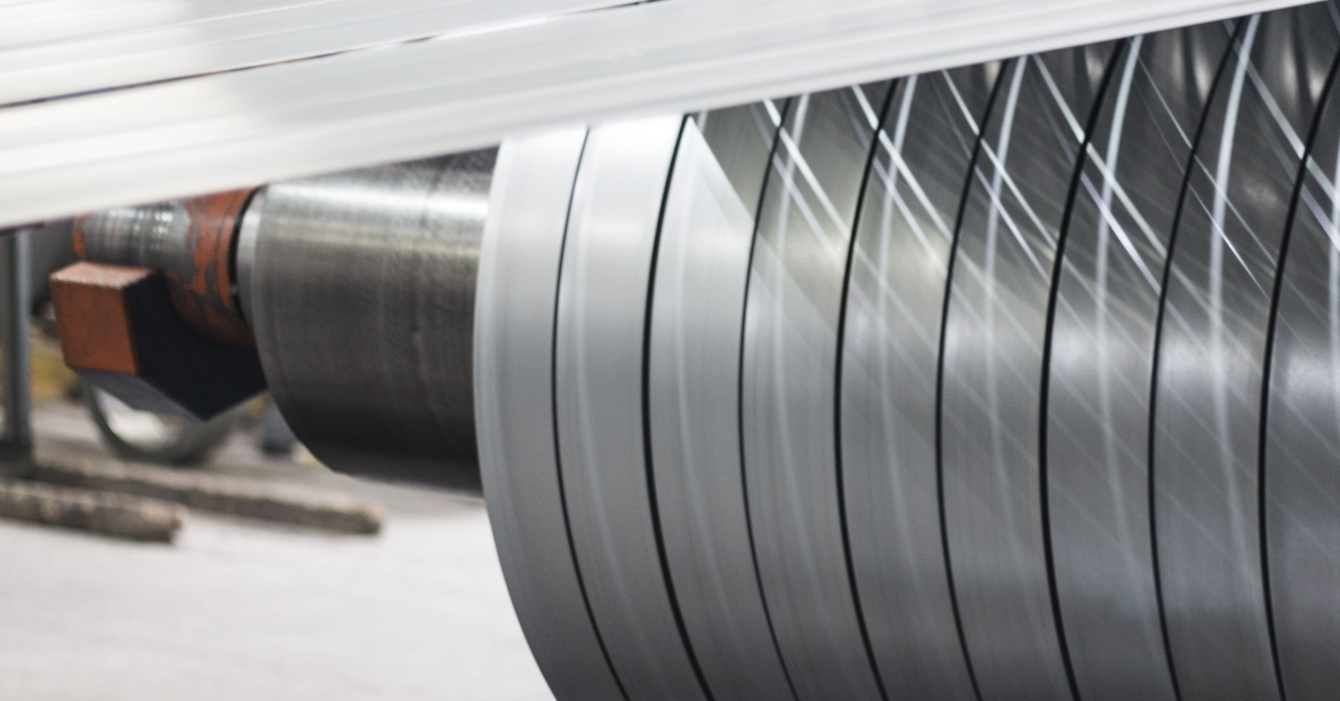

Sliced Sheet

The production of materials in the quality and size requested by our customers is made from suitable roll sheets according to the precise measurements requested by our expert slitting operators.

During the slitting process, intermediate checks are made at periodic intervals. After the slitting process is completed, the final checks are completed and the strapping and packaging process is carried out.

Advantage

- Customized Precision: Tailored to exact specifications for perfect fit.

- Reliable Quality: Rigorous checks ensure consistent high standards.

- Effortless Handling: Meticulous packaging for easy transport and reduced risk of damage.

We’re Here to Help You

How are sliced sheets customized to meet customer requirements?

Sliced sheets are produced from suitable roll sheets according to precise measurements requested by customers, ensuring they fit seamlessly into their intended applications.

What quality assurance measures are in place during the production of sliced sheets?

Intermediate checks are conducted at periodic intervals throughout the slitting process, followed by final inspections to ensure sliced sheets meet stringent quality standards, guaranteeing reliability and consistency.

How does the packaging process enhance the convenience of using sliced sheets?

After production, sliced sheets undergo meticulous strapping and packaging, ensuring easy handling and transportation while reducing the risk of damage during transit.